Mobilities

Bourgogne-Franche-Comté

6 laboratories

2 technology platforms

5 engineering schools

The AER BFC supports you

In connection with the Innovation and Ecological Transition Unit of the AER BFC, Ludovic DIERS, Mobility / Energy Project Manager, will help you to carry out your projects and to lead the sector.

“The pandemic, the rise in fuel prices and the evolution of travel practices are profoundly transforming the mobility sector. In addition, the challenge is to move towards a low-carbon sector by 2050, both in the use of means of transport and in their design and end-of-life management. The automotive, rail and cycle industries are facing brutal changes and must adapt their economic model, their product and industrial strategy in record time. Succeeding in these challenges is essential for the sustainability and development of the sector in our region, but it is also an opportunity to invent the mobility solutions of tomorrow.

For nearly 25 years I have held various technical, project management and supervisory positions in the automotive R&D sector. After an initial experience with a plastics manufacturer, I joined the PSA group, now Stellantis, at the Belchamp site in 2001. I participated in the development of the BVh2 and EMP2 platforms and their associated silhouettes/GMP. I joined the world of economic development at the beginning of 2022 and it is with this experience that I will accompany you in your projects.

06.83.74.05.03 – ldiers@aer-bfc.com

The support offered by the AER BFC takes different forms:

– Meetings with high-stakes companies,

– Participation in the animation of the ecosystem,

– Targeted prospecting in France and internationally,

– Engineering of business projects,

– Financial engineering,

– Land and business real estate.

A forward-looking ecosystem

Automobiles, trains, buses and two-wheelers are all mobility solutions in which Burgundy-Franche-Comté is constantly innovating. With the presence of international flagship companies such as Stellantis, Alstom, Lapierre and centres of excellence, innovation has long been anchored in the region’s DNA. The region thus supports companies in the development of tomorrow’s solutions, in particular autonomous, electric or hydrogenated means of mobility.

The players in the sector can rely on dedicated teaching centres that train qualified employees adapted to technological developments.

Finally, all of this is accompanied by a territorial desire to promote new means of mobility and to develop infrastructures that are consistent with the issues at stake: recharging stations, production of hydrogen and green electricity, secondary rail network, free-floating and bicycle paths.

6 reasons to choose the BFC Region

- Global players ;

- Specialised skills in mobility;

- A structured sector;

- France’s leading industrial region;

- A region that supports you;

- A history and culture linked to mobility.

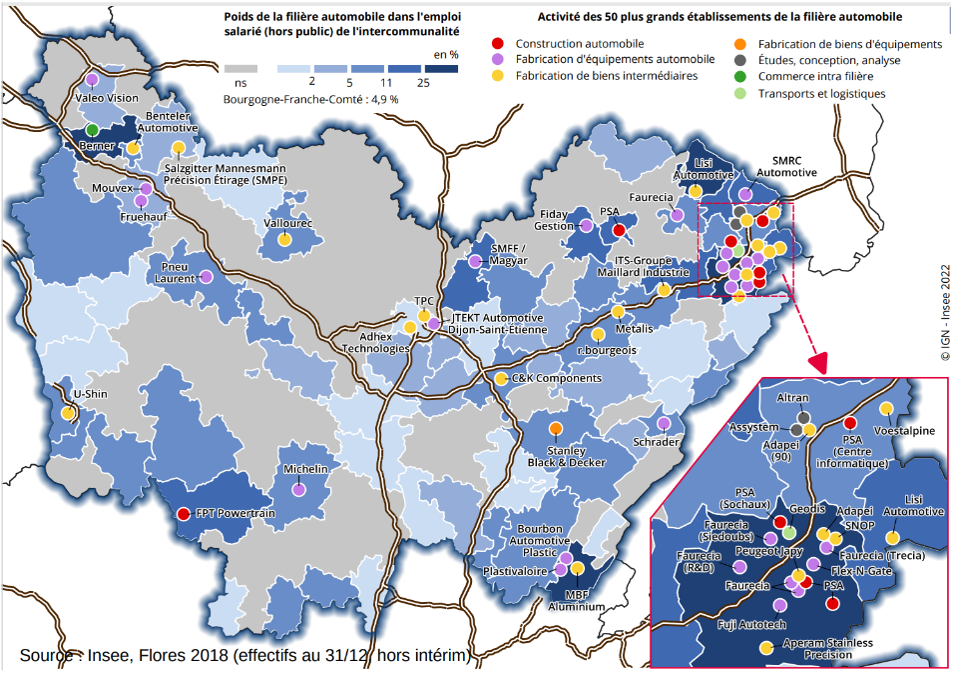

The automotive industry in Bourgogne-Franche-Comté

- 38,500jobs

- 370establishments

- 2competitiveness clusters

Automotive

Territory of the automotive adventure

The adventure began in 1912 with the creation of the Sochaux production site, which was then dedicated to Peugeot cars. The site had 40,000 employees and produced up to 510,000 vehicles per year. The manufacturer’s site, which today has become Stellantis, has been thoroughly modernised through a very ambitious workshop transformation programme called Sochaux 2022. The investment of more than 200 million euros was supported by the Bourgogne-Franche-Comté Region. This programme makes the Sochaux site one of the most modern and most efficient in Europe, but also one of the most virtuous thanks to the “Green Factory” part of the project, which aims to limit its impact on the environment and its consumption of natural resources.

Nearby, there is also the manufacturer’s vehicle of the future development site, Belchamp. This is a multi-skilled site capable of developing and validating a vehicle in its entirety. Major investments have been made to ensure its performance. The latest of these is the renovation of the aero-climatic wind tunnel.

In its wake, Stellantis is bringing along a whole ecosystem of suppliers and subcontractors who, by innovating, are helping to make the BFC a region of excellence in the automotive sector.

The region is also a land of motor sport and competition. Some thirty companies whose activities are wholly or partly dedicated to motor racing are located on the Magny-Cours Technopole, at the foot of the circuit of the same name. These companies, specialising in cutting-edge technologies derived from motor racing, participate in their own way in the development of tomorrow’s mobility solutions.

Some companies located in the region

Akka, AL-KO, Altran, Assystem, Baud Industries, Charlatte Manutention, Danielson, Delfingen, Erde, Faiveley, Faurecia Clean Mobility, Flex-n-Gate, Fruehauf, Groupe Simonin, Groupe Streit, Grupo Antolín, Jtekt Automotive, Ligier, Lisi, Magna Steyr, MMT, Michelin, Mygale, Magyar, Oreca, Plastic Omnium, Plastivaloire, Poclain Véhicules, R.Bourgeois, Remorques Louault, Schrader SAS, Segula, SMFF, Stellantis, Valeo Sécurité Habitacle, etc.

Partners to support you

- Aslog: ASLOG brings together more than 500 companies from all sectors to promote and build the supply chain.

- Robotics Valley: cluster dedicated to industry 4.0, robotics/cobotics and vision.

- Pôle Véhicule du Futur: supports companies in the areas of strategy, performance, innovation and promotion.

Skills in demand

The players in the sector find in the region the skills essential to their development and performance. Various establishments train students in the latest automotive technologies from the CAP to the PhD level.

For instance:

- ISAT – Institut Supérieur de l’Automobile et des Transports: the school trains engineers for all automotive and transport professions: the school trains engineers for all automotive and transport professions.

- ÉCOLE ESPERA SBARRO – Automotive Design: a 10-month course in automotive design techniques, combining theory and practice.

- MOBICAMPUS – qualifications and upgrading of skills. Structure of qualifications and upgrading of skills leading to a diploma or qualification, from CAP to doctorate.

- École des métiers de Dijon : trains for jobs in painting, maintenance and car bodywork.

They have benefited from our support

The German group, which specialises in the armouring of light vehicles, will start its activity at the end of 2022 on the former PSA Hérimoncourt site. Welp is planning an initial investment of 2.5 million euros for the renovation of buildings, as well as two envelopes of 800,000 euros for the purchase of equipment and machines and 500,000 euros for the implementation of training. In the long term, 80 jobs could be created. The region and the Pays de Montbéliard agglomeration community have supported the project in the search for land, aid for the rehabilitation of the site and recruitment.

Rebirth of the mythical sports car brand from the first half of the 20th century. The Nevers Magnicourt site is where the brand’s R&D subsidiary, which is in charge of developing the first hypercar, the D12, was established. It is in this basin that the company has found the skills and installations necessary for the development of this exceptional vehicle which embeds numerous innovations. Some of these technological bricks could be the answers to the challenges of tomorrow’s mobility. The region, Bpifrance and the Pôle Véhicule du Futur have mobilised to support the company.

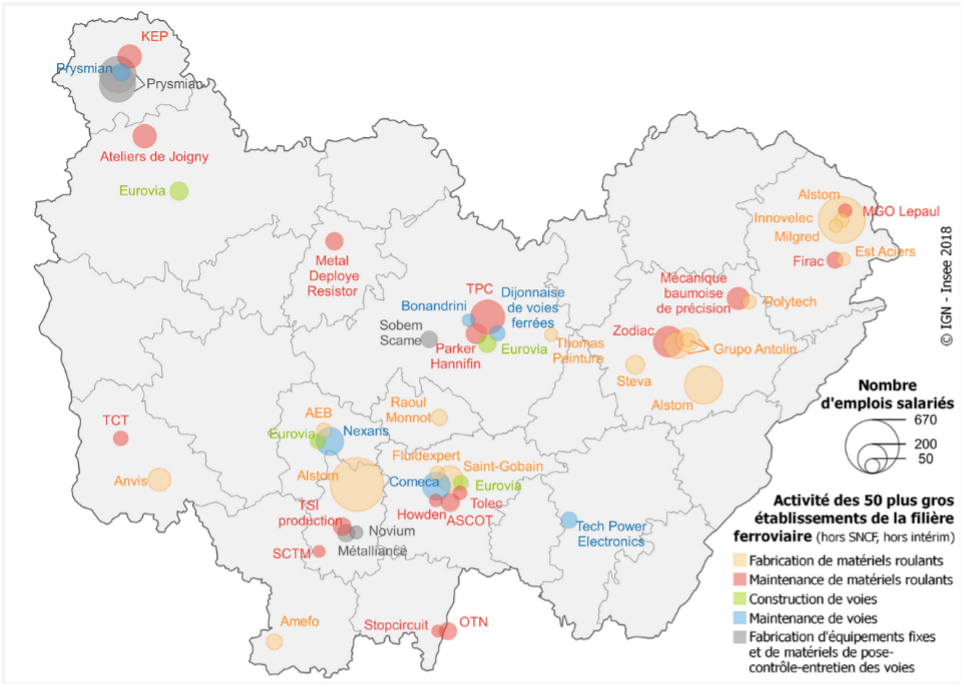

The railway sector in Burgundy-Franche-Comté

- 8,500jobs

- 150companies

- 1cluster

Railway

An emblematic sector in Bourgogne-Franche-Comté

The railway sector is represented in the region by major players such as Alstom or Eurovia and is based on 2 main types of activities: the manufacture and maintenance of rolling stock and the maintenance of traffic infrastructures.

Alstom’s history began at the end of the 19th century in northern Franche-Comté, in Belfort. Today, Alstom has four world-class centres of excellence in the region:

- Belfort (design and manufacture of TGV engines and locomotives)

- Ornans (design and manufacture of traction motors)

- Le Creusot (bogies and dampers)

- Saint-Denis-Lès-Sens (brake discs)

As proof of the performance of this sector in the region, Alstom recently won contracts to deliver trains and trams in Germany and Tel Aviv.

Some companies located in the region

A.C.E, Alstom, Amefo SAS, Anvis, Ateliers de Joigny, BDVF, Bonandrini, DVF, Jeantet Elastomères, Kremer, Matisa, OTN, SKF Slewing Bearings, Technicentre SNCF, etc.

Partners to support you

Mecateamcluster: located in Creusot Montceau, a national centre specialising in the design, production and maintenance of railway works equipment.

Skills in demand

Bourgogne-Franche-Comté is an industrial region with proven skills in machining, mechanics and boiler making, inherited from the coalmines and the royal foundries. Its industry has invented and integrated new techniques to improve the comfort, safety, carbon footprint and performance of railway installations and equipment. The region thus has the skills necessary for the development of the sector and for each stage of the manufacture and maintenance of rail networks, the design and construction of rolling stock.

ISAT: Automotive, aeronautics and transport engineering school: the school trains engineers for all automotive and transport professions.

Campus Mecateam: The Campus is a training centre dedicated to the maintenance of railway works equipment and offers training courses in the maintenance of railway works equipment. The aim is to train more than 5,000 people over the next 10 years in order to meet the growing needs of companies in the sector for initial and ongoing training, to harmonise working methods, to improve know-how and to increase the productivity of worksites. The training centre will be able to rely on an educational platform that is unique in France.

The railway sector in Bourgogne-Franche-Comté

- 1,700jobs

- 180establishments

- 1Centre de formation

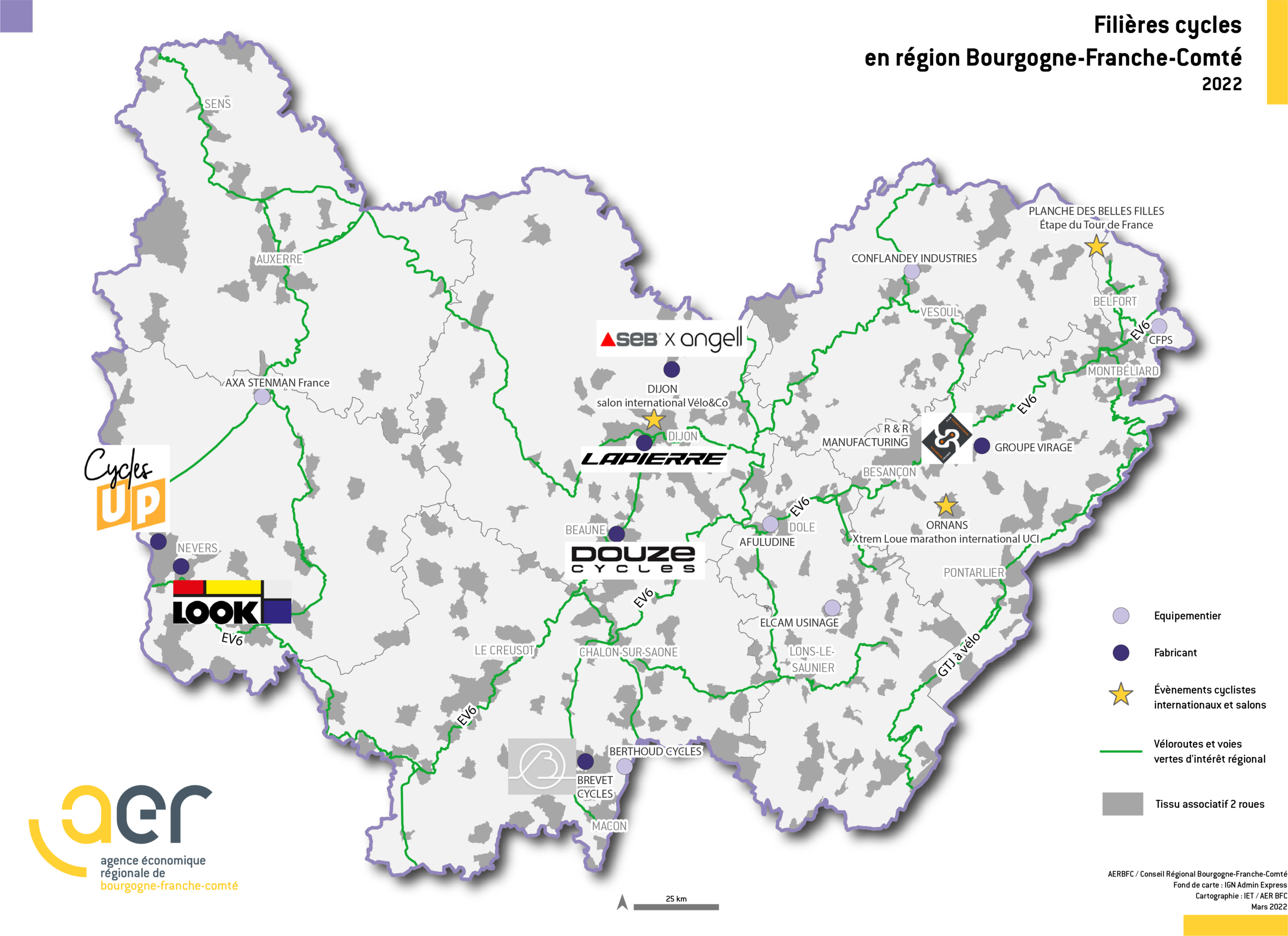

Soft mobility - A growing sector

Growth of soft mobility

Motivated by the cost of fuel, awareness of climate issues, and their agility in the city, scooter cycles and other cargo bikes have gone from being a piece of sports equipment to a means of mobility in their own right. As a complement or even an alternative to the car, these means of mobility have grown significantly in recent years and the trend is accelerating. USC projections predict that bicycle sales will increase sixfold by 2030, driven by the electrically assisted bicycle.

Burgundy-Franche-Comté is a region that puts soft mobility at the centre of its mobility strategy, with three agglomerations equipped with a fleet of self-service bicycles, 2,000km of cycle paths and over 850 clubs and associations. There are also historical and international manufacturers:

- Look: Established in BFC for 70 years, this manufacturer has won numerous Olympic titles and is distinguished by its unique know-how in the design of carbon bikes.

- Lapierre: also distinguished by numerous world championship titles, this Dijon-based group produces 150,000 bikes per year.

- Douze Cycles: European leader in cargo bikes

Also note the presence of Peugeot MoTo Cycle (PMTC), which develops and produces a whole range of electric scooters. Finally, in the region, you will find a show dedicated to bicycles: VELO&CO, an opportunity to promote your products and create the partnerships necessary for your development.

Partners to support you

Pôle Véhicule du Futur: In addition to its expertise in the fields of service mobility, materials and processes, the PVF also supports you in your innovation projects;

Pôle Polymeris: reference in innovation for the plastics, rubber and composites sectors.

Des compétences recherchées

École des métiers de Dijon : training in cycle mechanics.The entire cycle industry can rely on the skills and know-how of the automotive world. Electronics, injection, assembly of sub-assemblies, painting, welding, industrial performance. So many areas in common between the cycle and automotive industries.

They have benefited from our support

The H project of Douze Cycle, gave birth to an innovative cargo bike taking the best of the two previous versions. The project also included the desire to relocate their production and supplies to France and Europe. The frame is thus designed and manufactured in France.

An eco-design approach was also carried out in order to limit the ecological footprint of the project. The ADEME (Agency for the Environment and Energy Management), the CETIM (Technical Centre for Mechanical Industries) and the AER BFC, through its Ecological Transition Pole, supported the project to make it a model of virtue.